Plate bending machines

Hydraulic Four Roller Plate Roll bender

Two Roller Steel Bending Machine

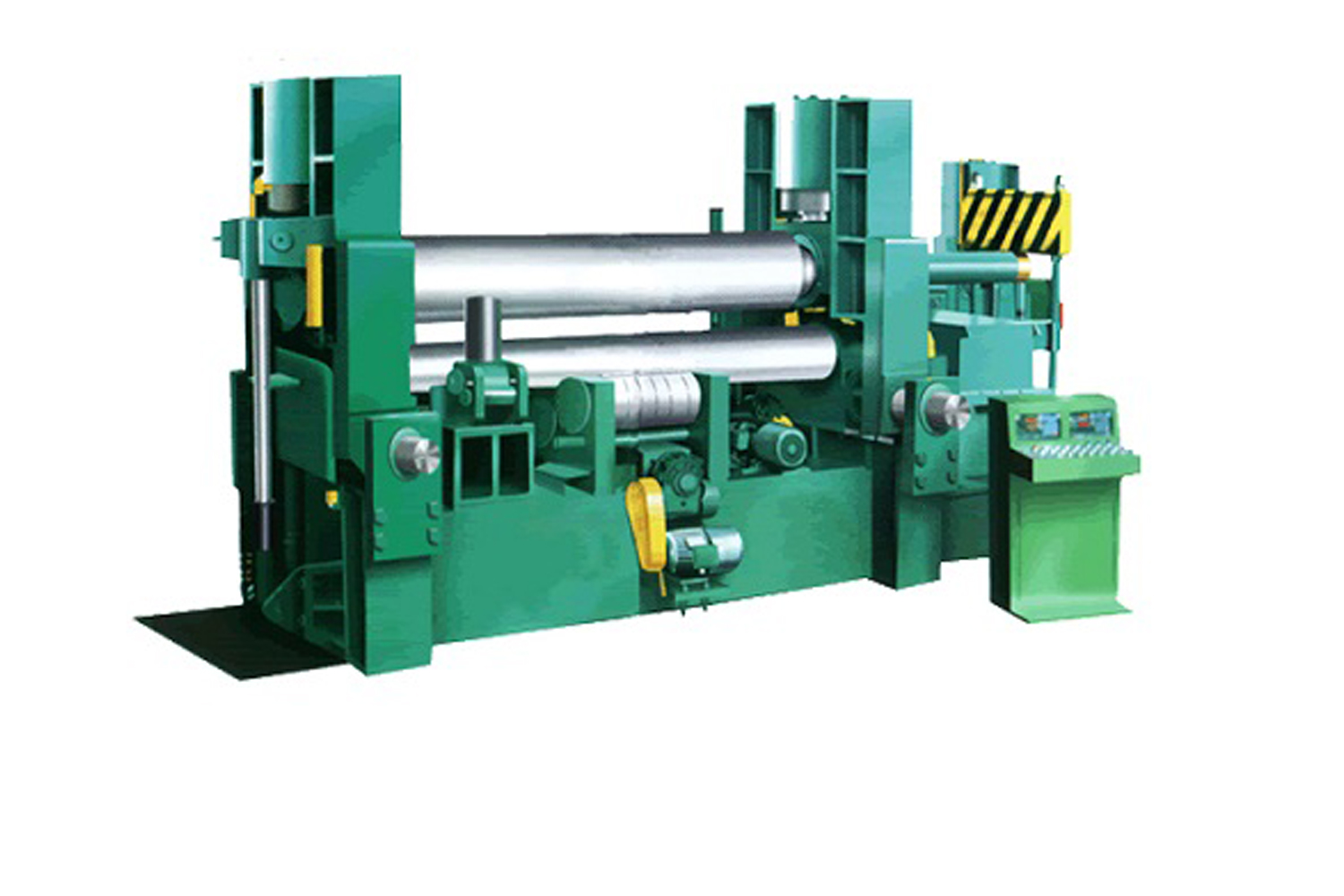

Three Roller Bending Machine

Four Roller Rolling Machine

Profile bending machine

Auxiliary products

Upper Roll Bending Machines

Industry News

Five major process features of 3-roller plate rolling machine

Plate rolling machine is a kind of equipment used for metal material rolling processing. According to the principle of three points forming a circle, the relative position change and rotational motion of the workpiece are used to make the plate produce continuous plastic deformation to obtain a workpiece of a predetermined shape.

Three-roller plate rolling machine is a general-purpose equipment that can roll metal plates into workpieces including circular, arc, rectangular or other shapes. The three-roller plate rolling machine consists of three rollers and can accurately roll metal materials into the required shape.

The upper roller of the three-roller plate rolling machine can be lifted vertically. The hydraulic transmission of vertical lifting is obtained by the hydraulic oil in the hydraulic cylinder acting on the piston rod; the lower roller is driven by rotation, and the output gear of the reducer is meshed to provide torque for the plate rolling. There is a roller at the bottom of the lower roller, which can be adjusted. The upper roller is in the shape of a drum, which improves the straightness of the product and is suitable for ultra-long specifications and various cross-sectional shapes of tanks.

The main features of the three-roller asymmetric plate rolling machine: The structure of the machine is three-roller asymmetric, the upper roller is the main drive, the lower roller moves vertically to clamp the plate, and meshes with the upper roller gear through the lower roller gear, and serves as the main drive at the same time; the side roller moves up and down, with the dual functions of pre-bending and rolling. Compact structure, easy operation and maintenance.

Technological features of three-roller plate rolling machine

1. High performance---full hydraulic drive, automatic welding;

2. High motor power----the main motor has high power, high efficiency, fast delivery, and a variety of applicable types;

3. High strength---the material is exquisite, the structure is stable, the use is safe, and the machine has good use effect;

4. Good safety----sturdy and durable, long service life, beautiful appearance, stable machine performance;

5. Wide applicability----applicable to mechanical industries such as boilers, chemicals, mining, construction, and shipbuilding.

Conclusion

The three-roller plate rolling machine is a commonly used metal processing equipment that can roll metal plates into round, arc-shaped and conical workpieces within a certain range. The equipment has a simple and compact structure and reliable quality, and is widely used in boiler, shipbuilding, petroleum and other machinery manufacturing industries.