Plate bending machines

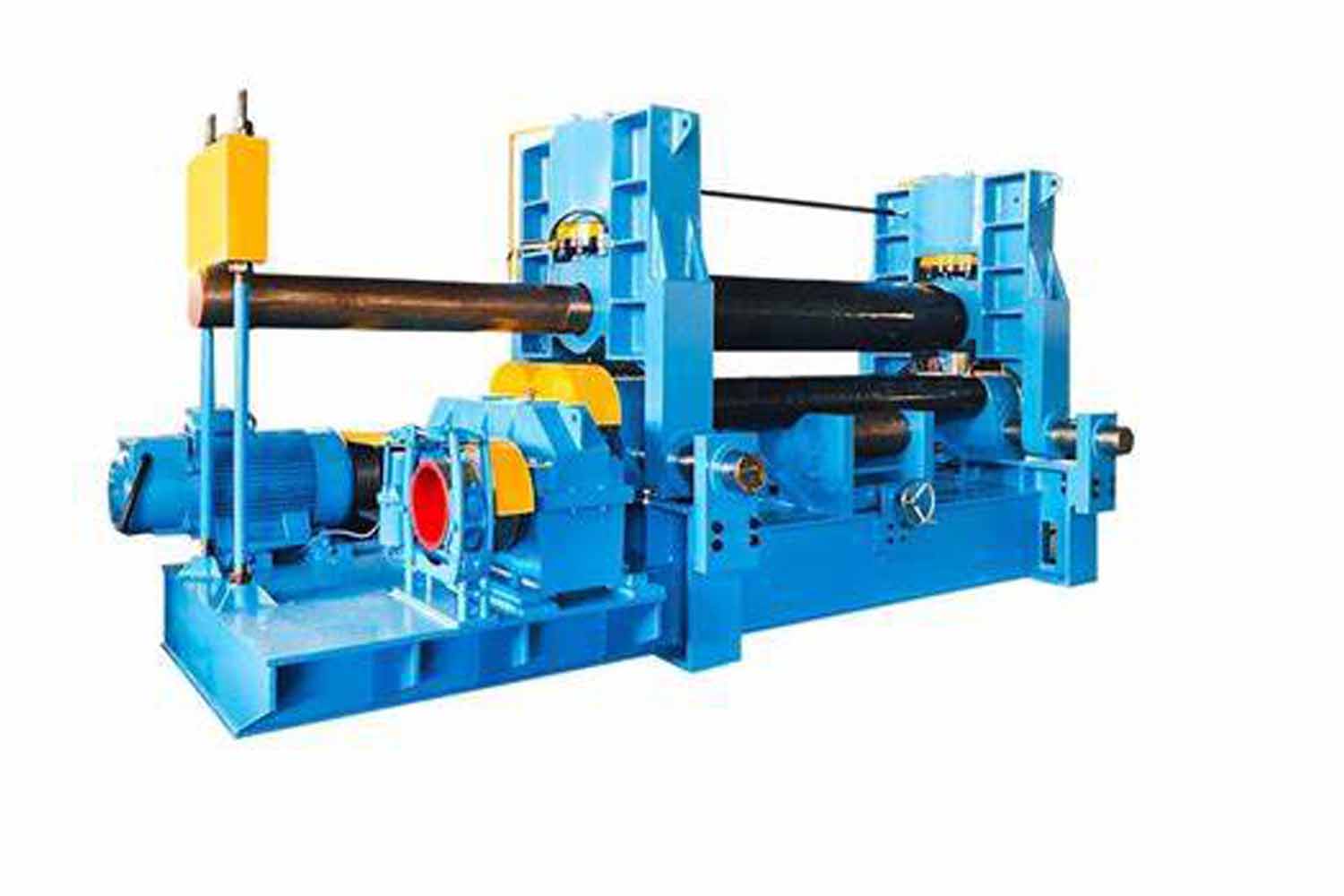

Hydraulic Four Roller Plate Roll bender

Two Roller Steel Bending Machine

Three Roller Bending Machine

Four Roller Rolling Machine

Profile bending machine

Auxiliary products

Upper Roll Bending Machines

Industry News

Features Of Four-Roller Plate Rolling Machine

Plate rolling machine is a kind of forging machine equipment that can bend non-metallic plates into cones, spheres, cylinders or other shapes. This function is widely used in manufacturing, boiler steam, chemical industry, non-metallic structures and machine manufacturing.

CNC four-roller plate rolling machine is a metal plate bending and correction machine, which is specially used for metal plate forming and bending. The pre-bending and curling of various specifications of cylindrical and arc-shaped workpieces can be completed after one loading. With the help of auxiliary devices, the conical cylinder can be rolled. It can also perform rough shaping work on metal plates.

Features of four-roller plate rolling machine

1. Automatic material alignment. The plate automatically aligns with the plate immediately when it is close to the rear roller.

2. The upper and lower rollers precisely clamp the plate at the tangent position to obtain an extremely short straight edge length (excellent pre-bending function).

3. Plate feeding. The plate is always clamped between the upper and lower rollers in the middle to ensure consistent and ideal positioning.

4. One-time rolling is completed. The entire cylinder can be completed by one rolling, including the pre-bending of both ends of the plate. Only the side roller position needs to be determined, and the plate needs to be automatically aligned without turning the plate.

5. Auxiliary equipment. Alignment, pre-bending and rolling are all centrally controlled. Pre-bending can be achieved quickly and safely without damaging the edge of the plate; the lower support contains a material alignment device to eliminate the misalignment caused by the rolling process. The upper support is mainly set up to cooperate with the rolling of large-diameter cylinders, and can replace overhead lifting equipment to cooperate with plate rolling.

Conclusion

The four-roller plate rolling machine can directly pre-bend the end of the plate without the help of other equipment molds, and the remaining straight edge is small; compared with the asymmetric three-roller plate rolling machine, it can roll the workpiece without turning the plate. This not only improves efficiency and ensures the quality of the workpiece, but also has a simple process, convenient operation, and reduces the labor intensity of workers.